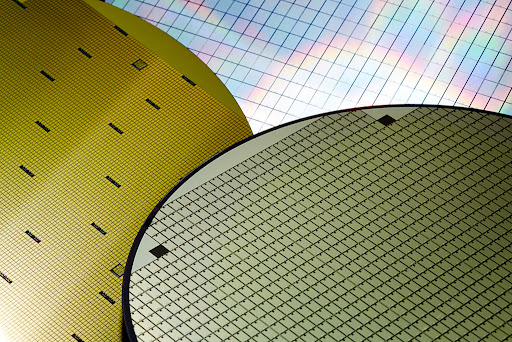

8-Inch SiC Wafers, A 2025 Mass Production Outlook

The rapid development of wide-bandgap semiconductor technology has made the progress of 8-inch SiC wafer production a focal point in the industry. Nexperia recently announced plans to invest $200 million in the research and development of next-generation wide-bandgap semiconductor products, including SiC and GaN, with plans to build 8-inch SiC MOSFET and low-voltage GaN HEMT production lines at its factory in Hamburg, Germany, expected to be realized within the next two years.

Although the current market share of 8-inch SiC wafer production is not high, it is an important technological route to reduce the cost of SiC, and significant progress has been made recently. Since Wolfspeed announced the launch of the world's first 8-inch SiC wafer factory in Mohawk Valley, New York, in 2022, the mass production of 8-inch SiC wafers has gradually been achieved.

Industry Chain Synergy, Accelerating Production Capacity

Close cooperation along the industry chain, from upstream to downstream, is key to the accelerated landing of 8-inch SiC wafer production capacity. Processes such as substrate, epitaxy, and wafer manufacturing all require production line modifications or new construction to adapt to 8-inch wafer production. This year, manufacturers including Tianyu Advanced Materials, ShuoKe Crystal, Jing Sheng Mechanical and Electrical, Tianke Heda, and Tongguang Shares have achieved small-batch production of 8-inch SiC substrates, while Tianyu Semiconductor, Han's Photovoltaic, and Baishi Electronics have the supply capability for 8-inch SiC epitaxial wafers.

In the field of wafer manufacturing in China, a breakthrough has been made, with Xilian Integrated announcing the successful production of 8-inch SiC engineering batches, becoming the first domestic wafer factory to start 8-inch SiC manufacturing. San'an Semiconductor also stated that its SiC full industry chain production line in Changsha will be operational this year. In addition, Nansha Crystal plans to expand Zhongjing Chip Source project to become the largest 8-inch SiC substrate production base in the country, with full production expected by 2025.

International Manufacturer Capacity Expansion

Internationally, Wolfspeed, as the earliest manufacturer to mass-produce 8-inch SiC substrates and wafers, recently announced that its Mohawk Valley silicon carbide chip factory has achieved a 20% wafer startup utilization rate, and plans to further increase it to 25% by the end of 2024. This indicates that Wolfspeed's SiC wafer factory production capacity is gradually being released, with substrate supply becoming a key factor in capacity growth.

Continuous Expansion of SiC Application Fields

The largest application market for SiC devices is undoubtedly electric vehicles. With the development of electric vehicle bus voltage from 400V to 800V, SiC devices play a crucial role in the 800V platform. In addition, driven by SiC manufacturers, SiC devices are also continuously expanding into new application fields such as photovoltaic energy storage systems, where the increase in system voltage has led to a reduction in overall system costs.

Infineon Technologies launched a series of new 2000V silicon carbide MOSFET products, model IMYH200R, suitable for busbar systems up to 1500V DC, such as string inverter, photovoltaic energy storage equipment, and charging piles, effectively improving overall energy efficiency. This marks an important step for SiC MOSFET products in high-voltage application fields.

Active Layout of Domestic Manufacturers

Domestic manufacturers such as Taike Tianrun and Basic Semiconductor are also actively deploying SiC MOSFET products, showcasing 2000V series SiC MOSFET single-tube products, and planning to launch higher specifications of SiC MOSFET product series to meet the needs of 1500V photovoltaic systems.

Market Outlook

With the gradual landing of 8-inch SiC production capacity and the continuous advancement of technological innovation, it is expected that SiC will be applied in more fields, including server power supplies in the popular AI data centers. The cost reduction and efficiency increase of SiC will promote the further expansion of its market size and bring new growth opportunities to the industry. It is anticipated that by 2025, the mass production of 8-inch SiC wafers will become a reality, laying a solid foundation for the widespread application of wide-bandgap semiconductor technology.

Recommended Models

● Infineon S29GL128P11FFI020 is a high-performance NOR Flash memory device. NOR Flash is a type of non-volatile memory that retains its data even when the power is turned off, making it ideal for storing firmware, boot code, and other critical data that need to persist through power cycles.

● ADI DAC08ESZ is an 8-bit digital-to-analog converter (D/A converter) with a universal digital logic interface. The chip is designed for applications that require low cost and high speed performance, such as servo motor drivers, waveform generators, audio encoders, analog instrument drivers, programmable power supplies, and high-speed modems.

● Intel EPC2LI20is a Programmable Logic Device (CPLD/FPGA). This non-volatile memory is used to store configuration data for SRAM-based field programmable logic arrays (FPGAs). It is commonly used in applications where configuration information needs to be maintained after a power failure.

Website: www.conevoelec.com

Email: info@conevoelec.com