TMD: New Hope in Semiconductor, Potentially Replacing Si

Introduction

Semiconductor technology is the cornerstone of the modern electronics industry. Since the mid-20th century, silicon (Si) has been the dominant semiconductor material, supporting the rapid development of microelectronics. However, as Moore's Law approaches its physical limits, the performance improvement of silicon-based chips has hit a bottleneck. Against this backdrop, transition metal dichalcogenides (TMD), with their unique physicochemical properties, are seen as potential replacements for silicon, heralding the arrival of the next generation of semiconductor materials.

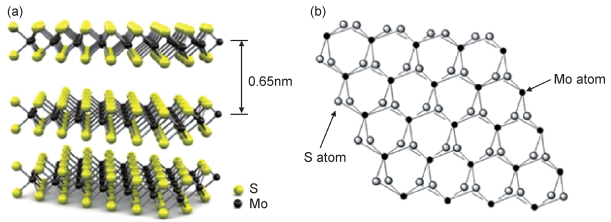

Overview of TMD Materials

TMDs are a class of compounds composed of transition metals (such as Mo, W, etc.) and chalcogen elements (such as S, Se, Te), with the chemical formula MX2. These materials possess a variety of crystal phases, including semiconductor 2H phase, semimetal 1T’ phase, and metallic 1T phase, exhibiting different electronic properties. Particularly, monolayer TMDs, due to their direct bandgap characteristic, have tremendous application potential in the field of optoelectronics.

Limitations of Si and Advantages of TMD

Although silicon is the leading material in the manufacturing of integrated circuits, its relatively small bandgap width results in limited electron mobility at the nanoscale. Moreover, silicon's poor optoelectronic performance restricts its application in the field of optoelectronics. In contrast, TMD materials feature adjustable bandgaps and layers, enabling higher electron mobility at the nanoscale, and possess excellent optoelectronic performance, demonstrating a broader application prospect in semiconductor devices.

Prospects and Challenges of TMD Replacing Si

The prospects for TMD to replace Si are broad, but it also faces challenges such as stability, manufacturability, and compatibility with existing technologies. Despite the outstanding performance of TMD materials in the laboratory, their performance in practical applications still needs further verification. In addition, the introduction of new materials may bring initial high costs, which need to be gradually resolved through technological innovation and mass production.

● Challenges faced:

◎ Stability issues: The stability and long-term reliability of TMD materials require further research.

◎ Manufacturing processes: The synthesis and integration processes of TMD differ from existing silicon-based technologies, necessitating the development of new manufacturing processes.

◎ Cost issues: The introduction of new materials may bring higher initial costs, which need to be reduced through mass production.

● Application prospects:

◎ Electronic devices: Smaller and more efficient transistors and logic gates.

◎ Optoelectronics: High-performance photodetectors, solar cells, and optical communication devices.

◎ Energy storage: Developing new types of batteries and supercapacitors using the catalytic and energy storage characteristics of TMD.

Conclusion

The replacement of silicon materials is not something that can be achieved overnight; the commercial application of TMD materials still needs to overcome many obstacles. However, with the continuous advancement of semiconductor technology, the rise of TMD materials brings new development opportunities for ic electronic industry. Despite challenges in stability, manufacturing processes, and costs, the potential of TMD to replace Si should not be overlooked. In the future, through the unremitting efforts of researchers, TMD materials are expected to be widely applied in the semiconductor field, promoting the electronics industry to enter a new stage of development.

Popular IC In Electronics

● The Nexperia USA 74LVCH245ABQ,115 is an octal bus transceiver with 3-state outputs, designed for high-speed data transfer and communication applications. This transceiver ic device is capable of operating with inputs driven from either 3.3 V or 5 V devices, making it suitable for use as translators in mixed 3.3 V and 5 V environments. The electronic ic is suitable for data communication (high-speed data transmission), conversion in hybrid voltage systems, automotive and industrial applications, etc.

● The Microchip MCP6479-E/ST is a high-performance operational amplifier (op-amp) designed for use in a wide range of applications including industrial, medical, and automotive systems that require robust performance and reliability. It features a gain bandwidth product of 3 MHz, which is typical for many applications requiring high-speed amplification. The device operates with a supply voltage ranging from 1.8V to 5.5V and has a low supply current of 140 µA, making it energy efficient.

● The NXP PCF51QM128VLH is a 32-bit microcontroller (MCU) IC belonging to the Coldfire V1 family with processing speeds of up to 50 MHz and 128 KB of FLASH storage. The microcontroller is equipped with 32 KB of RAM and has 64 pins, usually in an LQFP package. It is suitable for a wide range of applications such as industrial, automotive and Internet of Things, and is capable of stable operation over a wide temperature range from -40°C to +105°C. This op-amp ic is widely used in industrial automation control systems, automotive electronics, Internet of Things (IoT) and communication interfaces.

● The 74FCT16952ATPAG8 from Renesas Electronics is a high-speed, low-power 16-bit register transceiver consisting of two independent 8-bit Type D register transceivers with independent input and output control, allowing for independent control of bidirectional data flows. The device is designed with a power off disable output function, allowing for "hot swapping" when used as a backplane driver. The 74FCT16952ATPAG8 operates in a temperature range of -40°C to +85°C and is available in 56-pin SSOP and TSSOP package options. The logic ic is mainly used in the fields of data communication, industrial automation, automotive electronics and computers.

Website: www.conevoelec.com

Email: info@conevoelec.com