Solid-State Batteries: The Revolution in Battery Technology

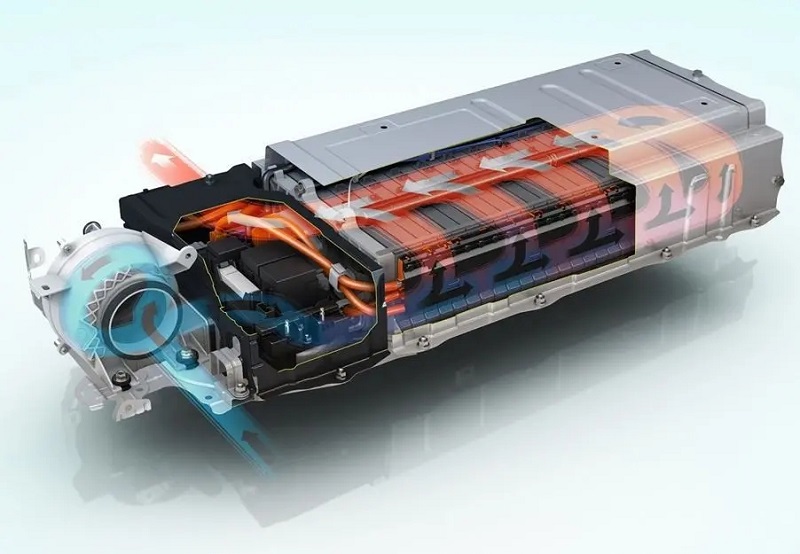

Solid-state battery technology, as a cutting-edge technology in new energy vehicles and industrial applications, is gradually moving from the laboratory to commercialization. Its high energy density, rapid charging and discharging capabilities, and long lifespan make it an important direction for future battery technology development.

Technical Challenges and Breakthroughs

The main challenges faced by solid-state batteries include slower charging and discharging rates and faster capacity degradation. The key to improving charging and discharging rates is the ionic conductivity. The ionic migration barrier in solid-state electrolytes is more than ten times that of liquids, resulting in lower ionic conductivity. However, with continuous technological advancements, these issues are gradually being resolved. Overseas companies such as Maxell and Toyota are also actively promoting the research and development and industrialization of solid-state battery technology.

Raw Materials and Technical Pathways

The raw materials for solid-state batteries mainly include positive and negative electrode materials, separators, and solid-state electrolytes. Mainstream manufacturers are laying out a development path from semi-solid to solid-state, with the core change being the introduction of solid-state electrolytes and new types of negative electrode materials. Solid-state electrolytes are mainly divided into oxide electrolytes and sulfide electrolytes, with the former having an advantage in stability and the latter in conductivity. Overseas companies such as Samsung SDI and LG Energy Solution are also actively deploying sulfide and polymer electrolyte routes.

Industrialization Progress

GAC Group released a solid-state battery at its technology conference, using third-generation sponge silicon anodes and high-capacity solid-state cathode technology, with an energy density of over 400Wh/kg. GAC plans to complete the development of solid-state batteries by 2026 and first equip them in its Haobo models. This progress marks an important step for solid-state battery technology in practical applications. At the same time, Maxell announced that it will start mass production of solid-state batteries for industrial equipment as early as 2026, choosing a factory in Kyoto Prefecture as the candidate site for the solid-state battery factory.

Strategic Layout of Domestic and Foreign Enterprises

Strategic Layout of Domestic and Foreign Enterprises

Overseas companies are also very active in the strategic layout of the solid-state battery field. For example, Maxell plans to invest 10 billion yen in the field of solid-state batteries by 2030, with the goal of achieving sales of 30 billion yen from solid-state battery business alone. Toyota has the highest number of patents in solid-state battery technology worldwide, having gradually shifted from initial material exploration to cell prototyping, and announced the mass production of solid-state batteries by 2027 or 2028. Samsung SDI and LG Energy Solution are also actively advancing the development of sulfide and polymer electrolyte routes.

Several domestic companies have significant layouts in the field of solid-state batteries. For example, Qingtao Energy chooses the oxide route, planning to transition from semi-solid to solid-state, and is expected to mass-produce the first solid-state battery in 2026. Weilan New Energy mainly takes the oxide + polymer route, planning to achieve mass production of solid-state batteries around 2027. CATL focuses on the sulfide solid-state route, planning to produce a small batch in 2027.

Market Prospects

With the global consensus on reducing carbon emissions deepening, the demand for electric vehicle markets is rapidly expanding. The high energy density, rapid charging and discharging capabilities, and long lifespan of solid-state lithium batteries will greatly promote the development of electric vehicles. It is expected that by 2030, the global shipment of solid-state batteries will reach 614.1GWh, and the market size will exceed 250 billion yuan. The commercialization prospects of solid-state battery technology are broad, and it is expected to be widely used in electric vehicles, industrial equipment, consumer electronics, and energy storage.

Conclusion

As a battery technology with great potential, solid-state batteries are gradually being commercialized. With continuous technological breakthroughs and the expansion of the market, solid-state batteries are expected to become mainstream battery technology in the next few years, promoting the development of new energy vehicles and industrial applications. The active layout and technological innovation of global companies will further accelerate this process, bringing new opportunities for the development of global energy technology.

Electronic PMIC Solutions

● AMS1117-3.3 is a 3.3V output voltage forward low voltage differential regulator, suitable for high efficiency linear regulators, switching power supply regulators, battery chargers, active minicomputer system interface terminals, laptop power supply instruments power management batteries. It has stable output voltage, overcurrent protection, overheat protection, low voltage difference, small package and so on.

● The LMZ31710RVQ is a 2.95V to 17V, 10A step-down power module with current equalizing capabilities in a QFN package. It is used in broadband and communication infrastructure, medical equipment and other fields.

● The LM1117IMPX-3.3/NOPB is a linear regulator with current limiting and thermal shut-off functions. It can be used in a variety of power management applications, including electronic devices, consumer electronics, industrial control systems, etc., especially where a stable 3.3v voltage is required.

● SPX3819M5-L-3-3/TR is a LDO Voltage regulator produced by MaxLinear, featuring low noise, high precision, low power consumption, reverse battery protection, overcurrent protection and so on. It is widely used in all kinds of electronic equipment requiring stable voltage output.

Website: www.conevoelec.com

Email: info@conevoelec.com