The Essential Role and Selection Guide of Battery Monitoring Units (BMU)

Within the Battery Management System (BMS), the Battery Monitoring Unit (BMU) plays an indispensable role as a core component ensuring the safety, performance enhancement, and lifespan extension of energy storage products. The BMU is responsible for real-time monitoring of key parameters of individual batteries or battery modules, including voltage, current, and temperature. These data are crucial for assessing the battery's State of Charge (SOC) and State of Health (SOH).

Functionality and Importance of BMUs

The primary task of a BMU is to collect data and monitor the battery's voltage, current, and temperature. This monitoring data assists the system in accurately calculating the remaining battery capacity and predicting the battery's health condition. The SOC indicates the remaining battery capacity, while the SOH reflects the health status and lifespan of the battery. By continuously monitoring and analyzing these parameters, the BMU can detect potential issues in advance, thereby extending the battery life and ensuring the consistency and reliability of the battery pack. Moreover, the BMU is also responsible for implementing battery balancing strategies, improving the overall performance and lifespan of the battery pack through active and passive balancing techniques. The BMU must communicate data to other system components, such as the main controller and charger, typically following communication protocols like CAN or LIN, to ensure data accuracy, real-time performance, and reliability.

Role of BMUs in BMS Architecture

In the BMS architecture, the BMU usually works in conjunction with the Battery Cluster Management Unit (BCMU) and the Battery Array Management Unit (BAMS) to form a complete battery management system, achieving comprehensive management and protection of the battery. The BMU provides foundational data, the BCMU executes control strategies, and the BAMS conducts integrated management and coordination. This tiered management helps improve the adaptability and scalability of the battery system and is applicable to various application scenarios.

Considerations for Choosing a BMU

Selecting a good BMU is crucial for the performance of the BMS. The BMU, as a key component of the BMS, is responsible for monitoring and controlling individual batteries or battery modules. It is a core technology for ensuring the safety, improving the performance, and extending the lifespan of energy storage products. When choosing a BMU, several factors must be considered, including precise monitoring capabilities, communication capabilities, balancing management capabilities, and data management and system security. There are various BMU products on the market, such as TI's TIDA-010271, Oriental Motor's BMU30 series, Huashu Technology's BMU-S64T52CP1, and Huawei Digital Energy's BMU products, each with different features to meet different application requirements.

Technical Development Trends of BMUs

With the continuous advancement of battery technology, future BMUs will adopt higher precision measurement and sensing technologies to achieve real-time and accurate monitoring of battery status. The introduction of intelligent algorithms and data processing technologies will enable BMUs to predict battery status and issue fault warnings more accurately, enhancing the real-time and response speed of battery management. In addition, the application of wireless communication technology may improve the flexibility and convenience of BMUs.

Conclusion

The BMU is one of the key technologies to ensure good battery performance and extend battery life. Choosing a good BMU requires a comprehensive consideration of various factors, including monitoring accuracy, protection mechanisms, balancing management capabilities, data management, and system security. With the continuous advancement of technology, future BMUs will be more intelligent and integrated, providing stronger support for battery management systems to ensure the safety, stability, and efficient operation of battery systems.

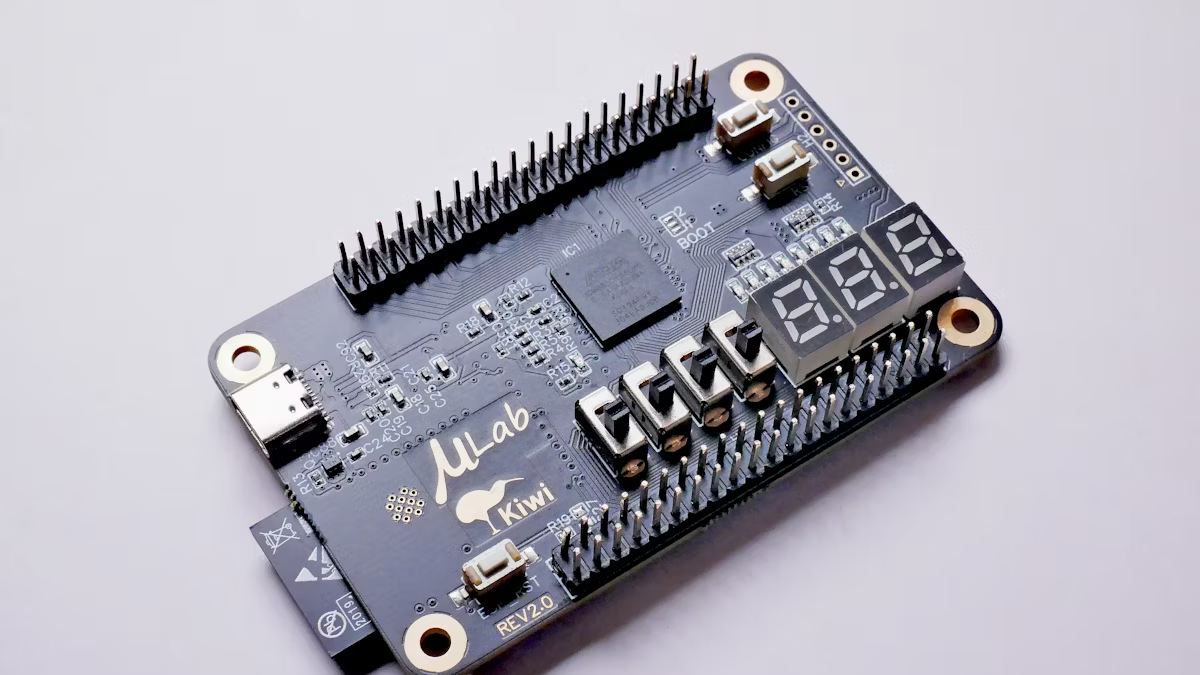

Conevo Battery Monitoring Units Component

● MT29F256G08CJABBWP-12IT: BTR is manufactured by Micron Technology Inc. The NAND Flash storage IC produced has a storage capacity of 256Gb, adopts MLC (Multi-layer cell) technology, supports synchronous/asynchronous interfaces, and has high storage density and fast data transmission speed. Support for multiple programming and erase modes, including page mode and block mode, improves the flexibility of data manipulation. MT29F256G08CJABBWP-12IT: BTR NAND Flash storage ics are widely used in areas requiring large-capacity storage and high-speed data transmission.

● The ADS825E is a CMOS Analog to Digital Converters (ADC) from Texas Instruments that also offers digital error correction technology to provide superior differential linearity for demanding imaging applications. The ADS825E CMOS ADC is suitable for a variety of applications requiring high-speed analog-to-digital conversion. Its high-performance conversion capability and low power consumption make it widely used in medical imaging, test equipment, computer scanners, communications and video digitization.

● KSZ9031RNXCA is a Microchip chip that integrates a three-speed (10Base-T/100Base-TX/1000Base-T) Ethernet physical layer transceiver for IEEE 802.3 standard applications. Its on-chip LDO controller supports 3.3V single-supply operation and generates a 1.2V core voltage via an external FET. KSZ9031RNXCA chip is suitable for a variety of network communication and industrial application scenarios with its efficient data transmission capability, energy saving features and diagnostic functions.

Website: www.conevoelec.com

Email: info@conevoelec.com