Denso and Fuji Electric Collaborate, $1.4 Billion SiC Semiconductor Investment for EVs

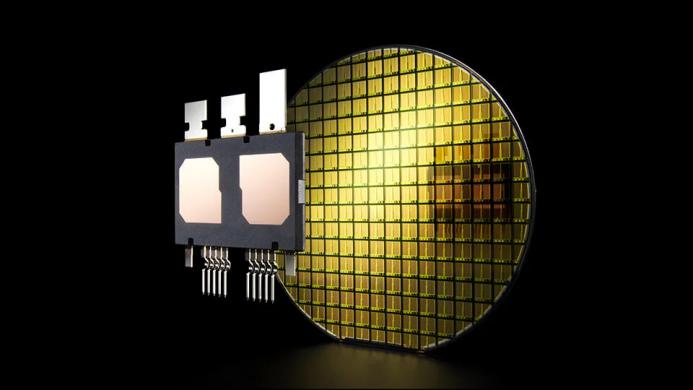

Against the backdrop of global decarbonization efforts, the demand for electric vehicles (EVs) has surged, leading to a corresponding increase in the demand for high-efficiency power semiconductors. Silicon carbide (SiC), as a novel semiconductor material, has emerged as an ideal choice in the EV sector due to its exceptional energy-saving performance and high-temperature stability. In this context, Japan's Denso and Fuji Electric have announced a joint investment of nearly 210 billion yen (approximately $1.4 billion) to develop and produce high-efficiency SiC power semiconductor devices for electric vehicles.

Collaboration Details

Denso, a leading global automotive parts manufacturer, has recently invested significant resources in the EV semiconductor field. Fuji Electric, on the other hand, possesses substantial technical acumen in the power semiconductor domain. This collaboration aims to leverage their respective strengths to meet the future demands of the EV market and enhance Japan's competitiveness in the global power semiconductor market. Denso will be in charge of SiC wafer production, while Fuji Electric will focus on the manufacturing of these devices. The two companies plan to expand their production facilities in Japan, with an expected annual output of 310,000 units by May 2027.

Denso, a leading global automotive parts manufacturer, has recently invested significant resources in the EV semiconductor field. Fuji Electric, on the other hand, possesses substantial technical acumen in the power semiconductor domain. This collaboration aims to leverage their respective strengths to meet the future demands of the EV market and enhance Japan's competitiveness in the global power semiconductor market. Denso will be in charge of SiC wafer production, while Fuji Electric will focus on the manufacturing of these devices. The two companies plan to expand their production facilities in Japan, with an expected annual output of 310,000 units by May 2027.

To achieve this goal, Denso will reinforce its factory construction in Toyota City, Aichi Prefecture, and Minami-Kuwanami, Mie Prefecture, focusing on SiC wafer production. Fuji Electric plans to expand its factory in Matsumoto City, Nagano Prefecture, to specialize in the processing and packaging of SiC power semiconductors. Both parties will also jointly develop new SiC device technologies to further enhance product performance and reliability.

Investment and Government Support

The total cost of Denso and Fuji Electric's joint power chip business is expected to reach 211.6 billion yen (approximately $1.4 billion). Japan's Ministry of Industry has indicated that it will provide 70.5 billion yen in support to the two companies for the joint production of energy-saving SiC power semiconductor devices for electric vehicles. This collaboration will not only boost Japan's manufacturing capabilities in the SiC power semiconductor field but also have a profound impact on the global EV market. With the widespread application of SiC devices in electric vehicles, their energy-saving and high-efficiency characteristics will further enhance the competitiveness of electric vehicles, propelling the rapid development of the EV market.

Market Outlook and Technical Advantages

As global attention to environmental protection and sustainable development grows, the adoption rate of electric vehicles is climbing rapidly. It is projected that by 2030, electric vehicle sales will account for more than one-third of global vehicle sales. SiC power semiconductor devices exhibit excellent performance in high-power, high-frequency, and high-temperature environments, and are widely used in power electronics, new energy, and automotive electronics sectors. Compared to traditional silicon-based semiconductors, power semiconductors made from SiC materials can increase the driving range of electric vehicles by about 10%.

Future Prospects and Challenges

Although the collaboration between Denso and Fuji Electric has broad prospects, it still faces numerous challenges during implementation. On one hand, the production technology for SiC devices is relatively complex, requiring high-precision manufacturing equipment and strict production processes. On the other hand, as competition in the global electric vehicle market intensifies, the performance and cost requirements for SiC devices will also continue to increase. Therefore, Denso and Fuji Electric need to continuously strengthen their technological research and development and innovation capabilities to enhance product performance and reliability while reducing production costs to meet market demands. In addition, both parties need to closely monitor the dynamics of the global electric vehicle market, adjusting production plans and product strategies in a timely manner to address future market challenges and opportunities.

Conclusion

The collaboration between Japan's Denso and Fuji Electric is not only a response to market demands but also a strategic move by the Japanese government to strengthen domestic production and ensure supply capabilities comparable to leading European and American companies. Through this partnership, the two companies will be able to enhance their competitiveness in the global power semiconductor market and contribute to the technological advancement and market competitiveness of electric vehicles.

ConevoEmbedded ICs

Conevo is an independent ic component distributor, offers a wide range of ic chips such as transistor, power switch, op-amplifier, memory, MCUS, sensors, controllers and more. For more Conevo chips, click to see more.

● The MW6S004NT1 is a radio-frequency power LDMOS (transversally diffused metal oxide semiconductor) transistor that is primarily used in high frequency, high power wireless communication applications.

● The TLE6240GP is a power switch IC manufactured by Infineon Technologies for power distribution systems, especially for engine management and powertrain, safety and body applications in automotive and industrial applications.

● The OPA1688IDR is an operational amplifier launched by Texas Instruments (TI), which is mainly used for audio amplifiers, high-precision measuring instruments, sensor signals, and power signal conditioning and control.

Website: www.conevoelec.com

Email: info@conevoelec.com