TSMC's 2nm Process Accelerates: Advancing the Frontier of Semiconductor Performance

In the fierce competition of the semiconductor manufacturing industry, TSMC has once again demonstrated its formidable technical strength and market acumen. Recently, TSMC announced that the timeline for its 2nm (nanometer) process technology has been advanced by half a year, marking a step forward in the global 2nm manufacturing schedule. This news has not only shaken the industry but also filled global consumers with anticipation for the performance of future technological products.

Technical Progress and Pilot Production Results

TSMC's 2nm chip pilot production results have not only met expectations but have also broken through the 60% yield barrier, a performance that far exceeds industry forecasts. The core highlight of the 2nm process technology is the introduction of GAAFET (Gate-All-Around Field-Effect Transistor) technology for the first time, which can significantly enhance the performance of transistors while reducing power consumption. Specifically, at the same power consumption, the 2nm process is 10% to 15% faster than the 3nm process; at the same speed, power consumption is reduced by 25% to 30%.

Production Timeline Accelerated

Production Timeline Accelerated

The originally planned mid-2025 equipment introduction and end-of-year production for the Tainan factory have been advanced by half a year due to surging market demand. This decision not only accelerates the commercialization process of the 2nm process technology but also further consolidates TSMC's leading position in the advanced process market.

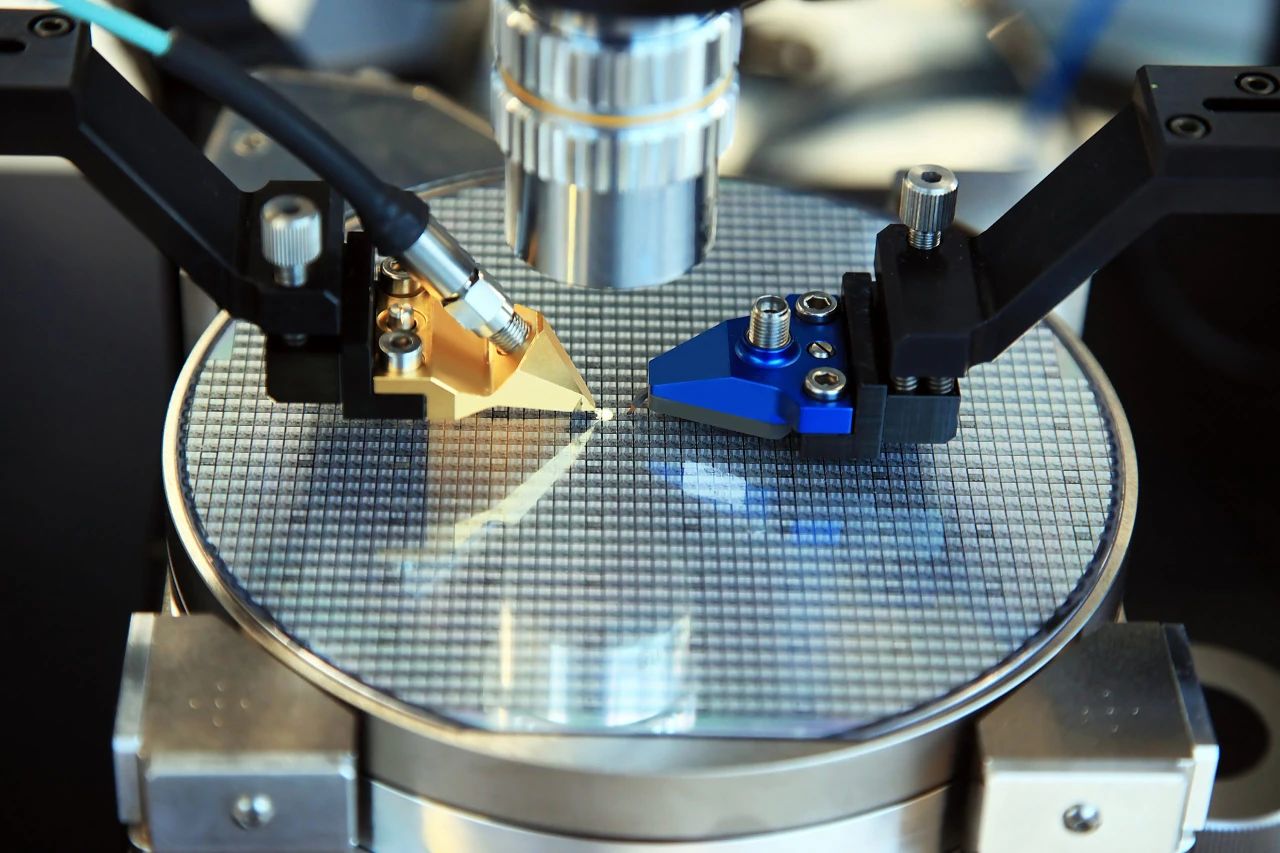

Factory Distribution and Capacity Planning

In preparation for the arrival of the 2nm process technology, TSMC has fully optimized its factory layout in Taiwan. In Tainan, the F22 factory will begin commercial production in the first quarter of 2026, with a monthly capacity of 30,000 wafers. At the Baoshan site, P1 and P2 factories will also produce 2nm process chips. The equipment for P1 has already been introduced in April 2024, with mass production expected in 2025 after the verification phase in the fourth quarter of 2024. The F20 factory in Hsinchu will also increase its capacity in the fourth quarter of 2025, with a monthly capacity of 30,000 wafers. By 2026, TSMC's monthly total capacity for 2nm process technology will reach at least 90,000 wafers, providing a stable and reliable supply of 2nm chips to global customers.

Market Prospects and Demand

With the explosive growth of AI applications, the demand for advanced process technology from major chip manufacturers has never been higher. As a top global chip foundry giant, TSMC's 2nm process technology has naturally become a sought-after commodity in the market. It is revealed that top global chip customers such as Apple and AMD will be among the first to use TSMC's 2nm process technology. Apple, which used TSMC's 3nm process technology in 2023, is expected to continue adopting more advanced 2nm process technology in the future.

Market Logic Behind Price Increase

Although the launch of TSMC's 2nm process technology is highly anticipated, the increase in wafer prices has also attracted widespread market attention. It is reported that the price of each 2nm process wafer may exceed $30,000, more than double the price of existing 4nm and 5nm processes. There is profound market logic behind this price increase. As technology continues to develop, the demand for high-performance, low-power chips is growing, and the 2nm process technology, as one of the most advanced technologies, has naturally become a scarce resource in the market. TSMC's price increase can lock in some profits in advance and avoid potential market risks, while also helping to recover investments more quickly and expand capacity to meet market demand.

Although the launch of TSMC's 2nm process technology is highly anticipated, the increase in wafer prices has also attracted widespread market attention. It is reported that the price of each 2nm process wafer may exceed $30,000, more than double the price of existing 4nm and 5nm processes. There is profound market logic behind this price increase. As technology continues to develop, the demand for high-performance, low-power chips is growing, and the 2nm process technology, as one of the most advanced technologies, has naturally become a scarce resource in the market. TSMC's price increase can lock in some profits in advance and avoid potential market risks, while also helping to recover investments more quickly and expand capacity to meet market demand.

Conclusion

As the countdown to the launch of TSMC's 2nm process technology begins, the competition in the global semiconductor manufacturing industry will also enter a new phase. As the leader in this field, TSMC will continue to lead the direction of global semiconductor technology development. In the future, we have reason to believe that with the widespread application of 2nm process technology, our technological products will become smarter, more efficient, and more convenient.

Conevo Logic ICs Distributor

Conevo is an independent distributor of semiconductor components offering a wide range of ic chips such as memory, operational amplifiers, converter, sensors, drivers, and more. Below are a few popular high-performance, cost-effective chip models. And for more electronic chip components, please click Conevo to learn more.

1. The AD7730BRZ is a 24-bit analog-to-digital converter chip produced by ADI, with a sampling rate of 1.2k per second, power dissipation of 125mw, operating temperature of -40°C to 85°C, and equipped with DSP, serial, SPI and other data interfaces.

2. The ADS1282IPW is a high precision analog-to-digital converter produced by TI, with a resolution of 31 bits, which can provide extremely high measurement accuracy, and is suitable for the application scenario of high-precision conversion of weak signals.

3. EP3C25F256C7N is a field programmable gate array (FPGA) chip produced by Intel/Altera, which contains 24,624 logic units and provides rich logic processing power to meet the needs of complex digital circuit design.

Website: www.conevoelec.com

Email: info@conevoelec.com