In-depth Understanding of Multi-layer Ceramic Capacitors (MLCC)

In the era of rapid advancements in electronic technology, various electronic components play crucial roles, with Multi-layer Ceramic Capacitors (MLCC) being one of them. As an indispensable basic component in the electronic industry, MLCCs are widely used in various electronic products, ranging from smartphones and tablets in daily use to automotive electronics, industrial control, communication base stations, and other fields.

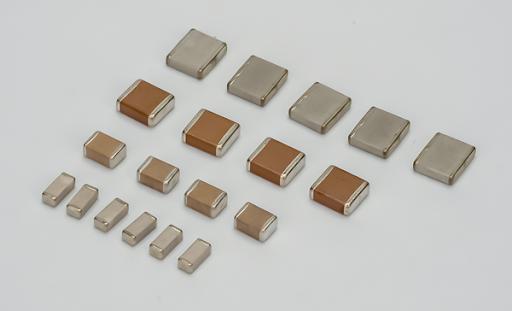

I. Introduction to MLCC

MLCCs are made by stacking ceramic dielectric films with printed electrodes (internal electrodes) in a staggered manner, followed by a one-time high-temperature sintering process to form ceramic chips. Metal layers (external electrodes) are then attached to both ends of the chip. Its working principle is based on the energy storage characteristics of capacitors, utilizing the polarization phenomenon of ceramic dielectrics under an electric field to store and release charges. When a voltage is applied across an MLCC, the ceramic dielectric becomes polarized, and charges accumulate on the electrodes, thereby storing electrical energy. When the voltage changes, the charges are released, completing the process of energy storage and discharge.

MLCCs possess many unique characteristics. Firstly, they have a small volume and large capacitance, enabling large capacitance values within a limited volume, which gives them a significant advantage in electronic devices with space constraints. Secondly, MLCCs exhibit good high-frequency characteristics and stability, enabling stable operation in high-frequency environments and ensuring the performance of electronic devices. In addition, they are highly reliable, with a long service life and the ability to adapt to various complex working environments.

The importance of MLCCs is self-evident. In electronic circuits, they play key roles such as filtering, coupling, and decoupling. For example, through the charging and discharging process, they can generate and discharge electrical energy, sometimes replacing small aluminum electrolytic capacitors and tantalum electrolytic capacitors. When paralleled with other components, they allow AC to pass while blocking DC, serving as bypass and coupling elements. They can also separate multi-frequency mixed signals in AC circuits, filtering out most low-frequency signals. Furthermore, they can remove short-lived surge pulse signals, absorb excess energy generated by voltage fluctuations in the circuit, and ensure the stable operation of electronic devices.

II. Popular MLCC Models

There are various popular MLCC models on the market, widely used in various fields due to their different capacitance values, voltage ratings, sizes, and packaging forms. For instance, models such as TDK's C1005X5R1A105K050BC, KEMET's C0603C104K5RACTU, and AVX's 06036D104KAT2A are particularly suitable for 5G communication modules and electric vehicle battery management systems due to their ultra-small size and high voltage rating. Models like Murata's GRM155R71C104KA88D and Vishay's VJ0603Y104KXACW1BC, on the other hand, are preferred in consumer electronics and industrial control due to their high capacitance stability and temperature stability.

Furthermore, in response to growing market demand and technical challenges, major MLCC manufacturers have introduced new products. For example, Murata has launched an innovatively designed low-loss MLCC, which not only has a high voltage rating of 100V but also an ultra-small size, making it ideal for wireless communication modules. Samsung Electro-Mechanics has released the world's first ultra-small 1005-size MLCC for autonomous driving LiDAR, the CL05Y225KP66PN, primarily used in automotive applications such as Advanced Driver Assistance Systems (ADAS), body, chassis, and infotainment systems, providing stable power supply and precise signal transmission for LiDAR. TDK has also introduced a new 3225-size MLCC suitable for resonant circuit capacitors, snubber capacitors, and other applications, improving high-voltage resistance and preventing overheating issues.

III. Trends in MLCC Development

With the continuous progress of the electronics industry, major manufacturers have increased their R&D investments and introduced new MLCC-related products. Samsung Electro-Mechanics and TDK have recently showcased new products, and beyond the aforementioned offerings, they are continuously exploring ways to enhance MLCC performance to meet market demands for high-performance, high-reliability MLCCs.

From a trend perspective, MLCCs are evolving towards higher performance and reliability. On the one hand, with the development of automotive electrification, the demand for high-performance, high-reliability MLCCs is increasing. Different automotive application scenarios have varying performance requirements for MLCCs, such as LiDAR needing MLCCs for stable power supply and precise signal transmission, and high-voltage circuit challenges posed by SiC MOSFET applications requiring MLCCs to continuously improve their high-voltage resistance. Industry players are enhancing product performance through technological iterations to meet market demands. On the other hand, MLCCs are also moving towards miniaturization and compactness to adapt to the shrinking sizes of electronic products. Simultaneously, their capacitance is continuously being increased to meet the requirements of more high-performance electronic devices. Additionally, requirements for MLCCs' temperature characteristics, frequency characteristics, and other aspects are becoming increasingly stringent, prompting manufacturers to continuously engage in technological innovation and optimization.

IV. Conclusion

As a crucial basic component in the electronic industry, MLCCs play an irreplaceable role in modern electronic devices. With continuous technological advancements and changing market demands, the MLCC industry is also evolving. While major manufacturers introduce new products, MLCCs are continuously iterating towards higher performance, higher reliability, miniaturization, and compactness. In the future, MLCCs are expected to play important roles in more application fields, providing strong support for the development of the electronics industry.

Website: www.conevoelec.com

Email: info@conevoelec.com